With more than 130,000 commercial and industrial grade fasteners in inventory, our wide distribution network is positioned to get you the parts you need fast. Whether we’re keeping your bins full with a Vendor Managed Inventory Program or rushing emergency replacement parts with 24-hour on-call service, you’ll know that we’ve got you covered. Our HQ’s quality system is certified to AS9120 ...

At Blue Ribbon Fastener, we specialize in providing high-quality bolts and fastening solutions tailored to meet the demands of various industries. With a commitment to precision, reliability, and durability, we ensure that our products exceed performance expectations in even the most challenging applications. Our extensive selection includes a wide range of bolts, each manufactured to exact...

Delta Fastener Corp. supplies headed fasteners from only quality manufacturers. Our huge, readily available selection includes industrial bolts, nuts, washers, screws, etc. in a wide range of metal types and grades. Check out our online catalog or give us a call today for industrial bolts and more!

P&R is a manufacturer of industrial fasteners, specialty fasteners, automotive fasteners, stainless steel fasteners, aerospace and electronic fasteners. We provide over 60 years of experience in designing quality industrial fastener products. Give us a call so we can work together.

Chicago Nut & Bolt specializes in nonstandard products such as industrial bolts, stainless steel bolts, carriage bolts, titanium bolts, mil spec bolts and alloy bolts in any quantity. We will supply any shape or size depending on your requirements. We assure quality products and on-time delivery.

More J Bolt Manufacturers

J Bolts: Applications, Manufacturing, Benefits, and Buying Guide

J bolts are a specialized type of fastener featuring a partially-threaded steel shaft bent into a “J” shape. These versatile anchor bolts are designed to secure objects—commonly with the help of a nut—by embedding the hooked end into concrete or by hooking around structural elements such as rebar. The unique form of a J bolt makes it indispensable for concrete anchoring, foundation construction, steel erection, and a wide array of structural and industrial fastening applications. Their robust performance in both commercial and residential construction has made J bolts a staple in the toolkit of builders, contractors, engineers, and DIY homeowners.

Are you searching for the best J bolts for your project? Wondering how J bolts compare to other anchor bolts, or which material grade is suitable for your application? Read on to discover extensive information on J bolt uses, manufacturing processes, material options, load ratings, and guidance for selecting the right supplier.

What Is a J Bolt?

A J bolt is a steel fastener featuring a hook or “J” shape at one end and machine threads on the opposite end. This configuration enables the J bolt to be installed into wet concrete, with the hook securely anchoring the bolt as the concrete sets. Once cured, the exposed threads are available for attaching nuts, washers, or other hardware. J bolts are commonly used as anchor bolts in structural, mechanical, and civil engineering projects, delivering high holding strength and enduring stability, especially in load-bearing and seismic applications.

Manufacturing of J Bolts

Modern J bolt manufacturing employs advanced techniques to ensure consistent quality, strength, and corrosion resistance. The process generally involves:

- Material Selection: J bolts are typically manufactured from carbon steel, stainless steel (such as 304 or 316 grades for superior corrosion resistance), or zinc-plated steel for enhanced protection in harsh or outdoor environments. Specialty alloys may be used for high-strength or chemical-resistant applications.

- Cold Forging: The manufacturing method usually begins with cold forging, where a steel rod is shaped at room temperature by forcing it through dies under high pressure. This technique gives the bolt its initial straight form and creates strong, uniform grain structure for improved mechanical properties.

- Bending and Cutting: After the rod is cut to the specified length, a secondary die or specialized tooling forms the characteristic J-shaped curve. The bend angle and radius may vary based on application needs, such as embedment depth or required load transfer into concrete.

- Threading: Only the straight portion of a J bolt is threaded, typically using high-pressure rolling dies. Threads are precision-cut to ensure compatibility with nuts, washers, or other fastening components. Thread types and pitches conform to standards such as UNC, UNF, or metric as specified by engineering requirements.

- Finishing and Plating: The finished J bolts may undergo surface treatments—such as galvanization, zinc-plating, or passivation—to further enhance corrosion resistance and durability, especially in outdoor, marine, or chemical environments.

- Quality Control: Rigorous inspection protocols verify dimensions, thread integrity, bend consistency, and material strength, ensuring that each J bolt meets applicable standards such as ASTM F1554, A307, or custom project specifications.

Curious about the differences between stainless steel versus galvanized J bolts? Need help identifying the right J bolt thread type for your construction project? Contact a J bolt expert for technical guidance on material selection and custom manufacturing options.

Common Applications and Use Cases for J Bolts

J bolts are engineered to provide structural anchorage, stability, and reliable load transfer in a wide spectrum of industries. Their unique shape and mechanical properties make them the preferred anchor bolts for:

- Concrete Foundation Anchoring: J bolts are commonly set into fresh concrete to anchor columns, beams, light poles, or steel structures. The hooked end resists pull-out, making them ideal for foundation bolt applications and seismic reinforcement.

- Structural Steel Erection: In commercial construction, J bolts fasten steel columns and frames to concrete footings, ensuring precise alignment and secure load distribution.

- Roofing Installations: Roofing applications frequently utilize J or hook bolts to secure trusses, rafters, or structural supports to concrete or masonry surfaces, providing wind uplift resistance and long-term stability.

- Equipment and Machinery Mounting: Heavy machinery, industrial equipment, and generators are often anchored using J bolts to prevent movement, vibration, or tipping during operation.

- Pole and Tower Foundations: J bolts form the critical anchoring element in the base of light poles, signposts, communication towers, and wind turbines, where high tensile and shear strength are required.

- Pipework and Conduit Supports: J bolts can be used to suspend or secure pipes, tubing, and electrical conduits, especially in infrastructure and utility installations.

- Furniture and Modular Assembly: J bolts are sometimes employed in furniture manufacturing for internal assemblies, offering reliable joining of wood, metal, or composite materials.

- Retrofitting and Repair: Contractors and homeowners use J bolts for anchoring new structures to existing concrete, such as adding garages, decks, retaining walls, or seismic retrofits.

Industry-Specific Uses of J Bolts

- Automotive Industry: Used in truck and vehicle tool kit mounting, chassis reinforcement, and suspension component attachment.

- Industrial Fabrication: Essential for securing heavy equipment, conveyor systems, and storage racks to floors or foundations.

- Energy and Utilities: Anchor wind turbines, electrical substations, and solar panel arrays to concrete pads, ensuring stability under dynamic loads.

- Infrastructure Projects: J bolts are specified in highway, bridge, and railroad construction for anchoring guardrails, barriers, and signposts.

- Marine and Offshore Applications: Corrosion-resistant stainless J bolts are used for securing dock hardware, mooring cleats, and marine structures exposed to saltwater.

Factors to Consider When Selecting J Bolts

Choosing the right J bolt for your project is critical to ensure safety, structural integrity, and regulatory compliance. Consider the following key factors:

- J bolt diameter and hole size: The load-bearing capacity increases as the diameter of the J bolt increases. Selecting the correct diameter is essential for meeting engineering specifications and safety codes.

- Embedment length: The deeper the J bolt is embedded in concrete, the higher its resistance to pull-out and shear forces. Engineers should calculate embedment depth based on anticipated loads and local codes.

- Material selection: Will the J bolt be exposed to moisture, chemicals, or corrosive environments? Opt for stainless steel, galvanized, or specialty-coated bolts for enhanced corrosion resistance.

- Load requirements: What is the maximum tensile, shear, or dynamic load the J bolt must support? Evaluate the expected loads, including static, seismic, or vibration-induced forces.

- Thread type and pitch: Ensure compatibility with nuts, washers, or other hardware by matching thread size and pitch to project requirements.

- Concrete type and thickness: The compressive strength and thickness of the concrete will affect anchoring performance. Consult engineering guidelines for minimum embedment and spacing.

- Fixture dimensions and placement: Consider the size, weight, and location of the object being anchored, as well as the available space for bolt installation.

- Environmental conditions: For outdoor, marine, or chemical plant environments, choose material grades and coatings that offer long-term durability.

- Spacing and edge distances: Maintain proper spacing between J bolts and from the edge of concrete to avoid splitting or reduced holding power.

- Regulatory standards: Confirm that the selected J bolts meet relevant building codes (e.g., ASTM, ACI, or local specifications) for your project type.

- Installation requirements: Will the J bolts be installed before or after concrete is poured? Pre-installed bolts offer greater holding strength; post-installed options may require special adhesives or expansion anchors.

Benefits of Using J Bolts

J bolts deliver a range of performance, safety, and installation advantages in construction and industrial applications, including:

- Exceptional anchoring strength: The hooked end provides superior pull-out resistance in concrete, preventing bolt slippage and structural failure.

- Wide compatibility: Suitable for use with concrete, masonry, steel, wood, and composite materials in a variety of structural systems.

- Simple installation: J bolts are easy to set while concrete is still wet, allowing for precise alignment and quick fastening once the concrete cures.

- Versatile design options: Available in a range of diameters, lengths, thread types, and material grades to meet custom engineering and architectural requirements.

- Corrosion resistance: Stainless steel and galvanized J bolts offer excellent protection against rust and degradation, ensuring longevity in harsh environments.

- Cost-effective solution: J bolts are competitively priced and deliver reliable long-term performance, reducing maintenance and replacement costs.

- Compliance with standards: Manufactured to meet industry standards for safety and performance, including ASTM, AISC, and ACI codes.

- Improved installation efficiency: Pre-bent J bolts eliminate the need for on-site bending or fabrication, streamlining construction schedules.

Comparing J Bolts to L Bolts, U Bolts, and Other Anchor Bolts

When selecting the right anchor bolt for your application, it's important to understand how J bolts differ from L bolts, U bolts, and straight anchor bolts:

- J Bolts: Feature a curved “J” hook for superior anchoring in concrete; ideal for structural loads and seismic applications.

- L Bolts: Feature a 90-degree bend, used for anchoring lighter loads or for specific geometric constraints.

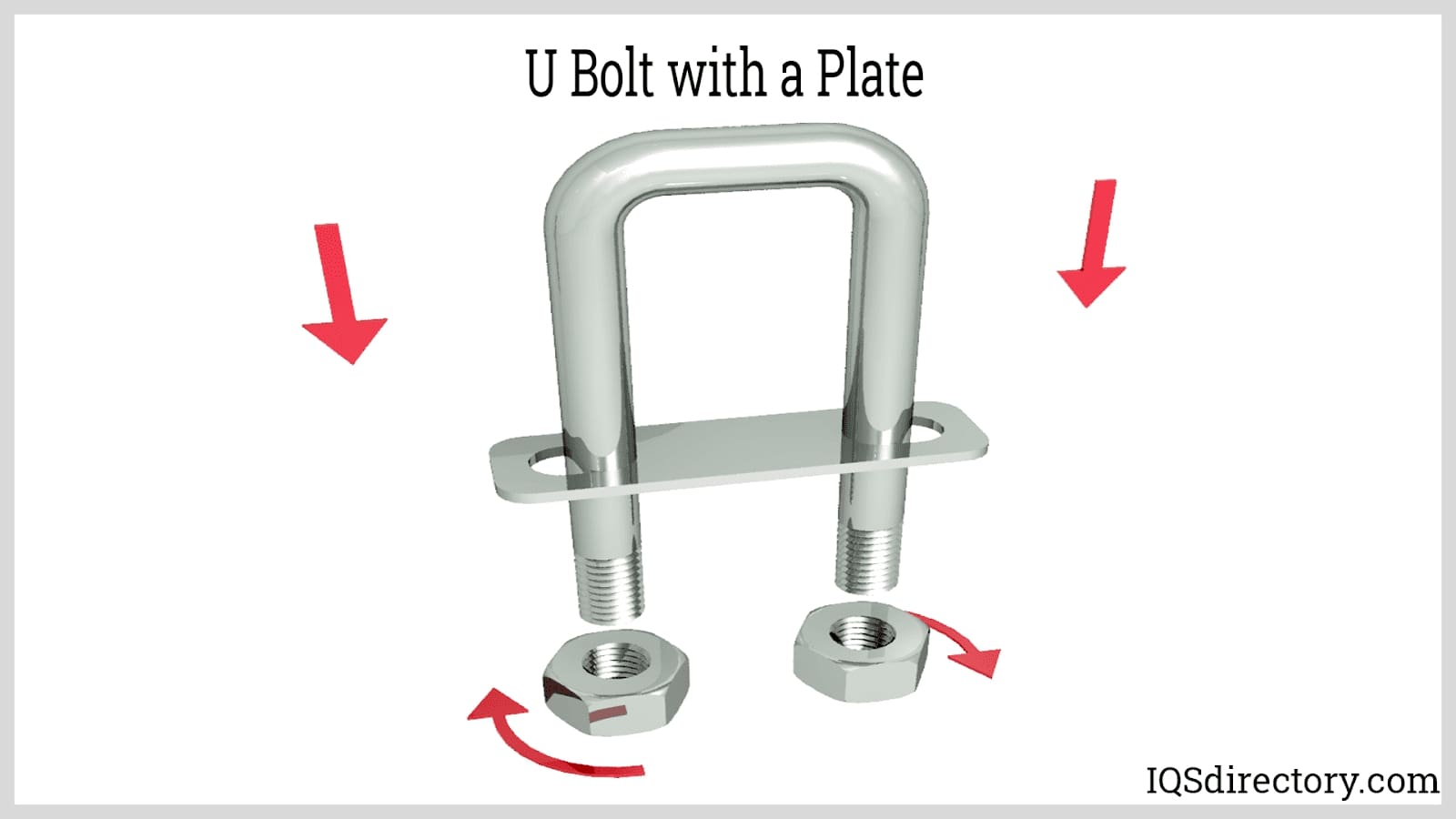

- U Bolts: Shaped like a “U,” typically used for clamping pipes, tubing, or round objects to flat surfaces.

- Straight Anchor Bolts: No bend, used in conjunction with mechanical expansion or chemical adhesives for post-installed applications.

How to Install J Bolts in Concrete

Proper installation is crucial for achieving maximum holding strength and code compliance. Here’s an overview of the recommended process:

- Determine the required bolt size, spacing, and embedment depth based on load calculations and code requirements.

- Prepare the concrete formwork and mark the exact locations for J bolt placement.

- Set the J bolts into the wet concrete, ensuring the threaded end is correctly positioned and aligned above the surface.

- Secure the J bolts temporarily (using templates or jigs) to maintain alignment and spacing during concrete pouring.

- Pour concrete and allow it to cure fully before applying any loads or attaching hardware.

- Install washers, nuts, or other fasteners to complete the anchoring system.

Frequently Asked Questions About J Bolts

- What is the standard thread size for J bolts? Common thread sizes include 1/2", 5/8", 3/4", and 1" UNC or metric equivalents. Custom thread sizes are available for specific requirements.

- How do I select the right J bolt material? For outdoor or corrosive environments, choose stainless steel or hot-dipped galvanized J bolts. For indoor, dry applications, zinc-plated or plain carbon steel may suffice.

- Can J bolts be used in existing (cured) concrete? While J bolts are typically set during concrete pouring, post-installed anchor systems (such as epoxy or expansion anchors) can sometimes be used as alternatives. Consult an engineer for retrofitting advice.

- Are J bolts reusable? J bolts embedded in concrete are generally considered permanent. If the fixture is removed, new anchor bolts will likely be required.

- What certifications or standards apply to J bolts? Look for compliance with ASTM F1554, ASTM A307, or specific project specifications for structural and seismic anchoring.

Choosing the Correct J-Bolts Manufacturer or Supplier

When sourcing J bolts for your construction, industrial, or OEM project, it’s essential to partner with a reputable manufacturer or supplier. Consider these decision factors:

- Check for ISO, ASTM, or AISC certifications to guarantee product quality.

- Review the supplier’s range of material options, custom fabrication capabilities, and coating services.

- Request engineering support for load calculations, sizing recommendations, and installation advice.

- Compare pricing, lead times, and minimum order quantities among multiple vendors.

- Read customer reviews and inspect sample products before placing bulk orders.

- Use our J-Bolts directory to compare at least 4 or 5 manufacturers, each with a business profile outlining their experience, certifications, and specialties.

Where to Buy J Bolts

You can purchase high-quality J bolts from specialized fastener distributors, industrial supply houses, or direct from manufacturers. Many suppliers offer online ordering, technical support, and custom fabrication for unique dimensions or material needs. Use our J Bolts Supplier Directory to find trusted sources near you, or request a quote for bulk orders and custom requirements.

Conclusion

J bolts are an essential component in modern construction and industrial projects, offering unmatched anchoring strength, versatility, and durability. Whether you’re anchoring steel columns in a new commercial building, securing equipment in an industrial facility, or retrofitting a residential foundation, choosing the right J bolt ensures the safety and longevity of your structure. For expert advice, technical resources, and a curated list of certified J bolt suppliers, contact our team or browse our resource library for further reading.

Have more questions about J bolts, anchor bolt specifications, or installation best practices? Speak with a fastener specialist for personalized assistance.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services